Pro 200 Porcelain Furnaces

The Pro 200 and the Pro

Press 200 Porcelain Furnaces

are affordable yet intelligently

designed with cutting edge

technology. They have

advanced cycles for e.max®,

In-Ceram®, Wol-Ceram®,

Captek™, sintered alloys

and advanced porcelain

products. The Pro 200

Series is completely lead

free in compliance with the

international RoHS directive.

The Pro 200 and the Pro

Press 200 Porcelain Furnaces

are affordable yet intelligently

designed with cutting edge

technology. They have

advanced cycles for e.max®,

In-Ceram®, Wol-Ceram®,

Captek™, sintered alloys

and advanced porcelain

products. The Pro 200

Series is completely lead

free in compliance with the

international RoHS directive.

All Pro Series Porcelain

Furnaces come standard with

a Vacuum Pump and a 3-Year

Warranty or 3,750 muffle

hours on unit (US & Canada

only). Should the unit ever

need servicing, direct access

to a service technician is

provided, greatly reducing the

turnaround time on repairs.

So, when you buy Whip Mix

Porcelain furnaces, you can

be sure you’re making an

investment in the long-term

success of your laboratory.

Advanced Technology

Programs & Temperature

- 200 open programs with

capability of expansion. - Extra insulation saves energy

costs. - Rated to 2200° F (1200° C).

Program Navigation

Selection knob with built-in enter switch allows for faster, convenient navigation and program entry.

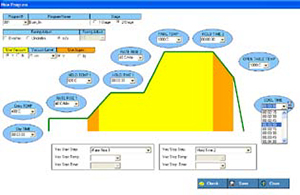

Master Suite Software

New graph-based application enables users to create, modify, print and transfer programs to furnaces directly from computers.

Easy to Read LCD Screen

- 4 line 20 characters LCD

display. - Displays many of the critical

monitoring elements.

Temperature Accuracy

- Factory set 3 point

temperature calibration for

unsurpassed accuracy. - 2 stage firing cycles for

e.max®. - Upgraded Thermocouple for

improved temperature

stability.

SPECIFICATIONS

Dimensions |

11"W x 16"D x 21"H |

Power Consumption |

1200W - Furnace Alone 1400W - With Pump |

Power Supply |

120 VAC ± 10% 50/60 Hz |

Muffle Windings |

Quartz Tubing |

Muffle Chamber |

3 ¾” W x 2 ½” H x 3 ¾” D |

Maximum Temperature |

2200ºF |

Shipping Weight |

59 lbs. |

Purchase Now! |

LEARNING

eBook

Why Temperature Control is Critical in Dental Ceramic Firing:

Download the eBook

Case Study

Making the Right Choice:

Download the Case Study

Whip Mix Offers You the Highest Quality Furnaces

Backed by a team of expert professionals for superior support.

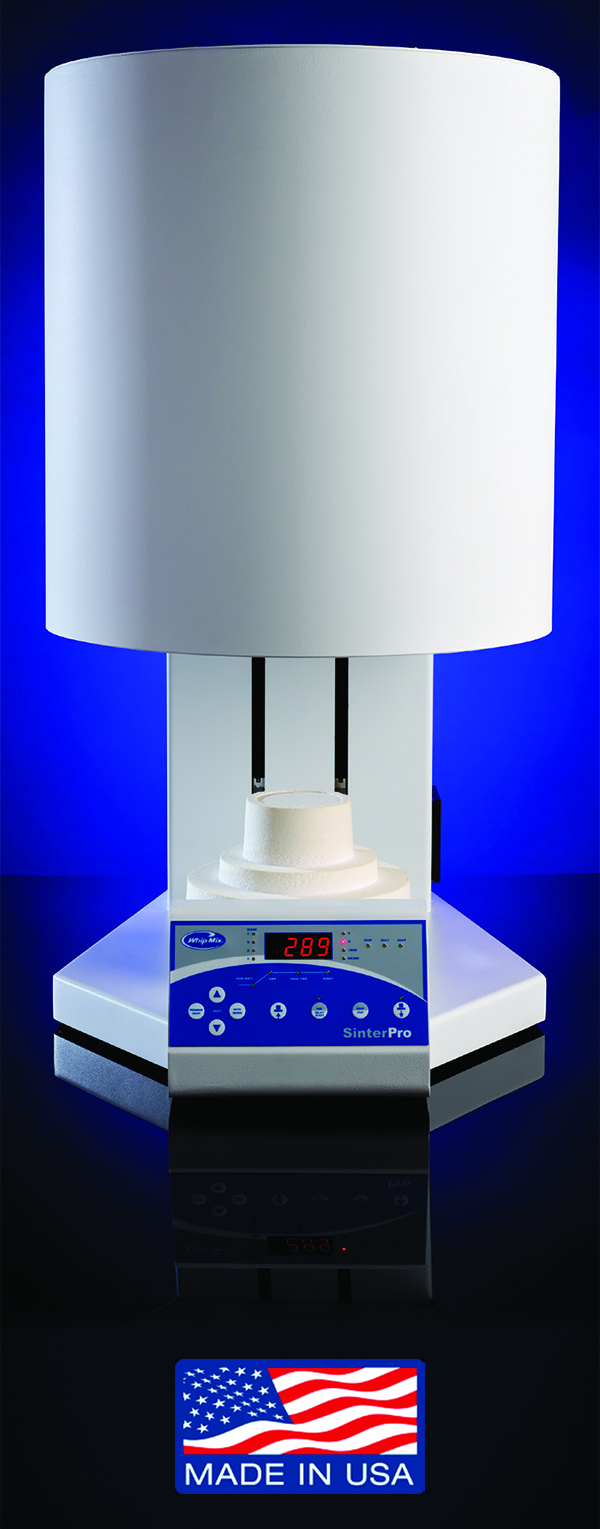

SinterPro

The new Whip Mix® SinterPro Sintering Furnace takes sintering to the next level. Multiple programs and multi-stage sintering allow for optimization throughout the process. SinterPro is easy to program, easy to use, and versatile. 30 user defined programs and shallow and deep trays that can be used in any combination make SinterPro a valuable addition in any laboratory setting. Its many advanced features give SinterPro true “Set and Forget” ease of use.

MULTIPLE PROGRAMS, MULTI-STAGE SINTERING

30 user-defined programs and four stage sintering allow for optimization of firing programs.

HIGH DENSITY PAYLOAD CAPACITY

Two trays with different heights give the furnace capacity real versatility. Use a shallow tray for basic single units and short span bridges, the deep tray for large

conventional and Prettau Bridges.

REDUCED AMPERAGE REQUIREMENTS

The low 16-20 amp draw requirement (depending on what country you live in)

means you will most likely not require custom electrical modifications.

POWER FAIL RECOVERY

If the power browns out or blacks out for a short time, especially at night when

unattended, the oven will automatically resume the firing cycle at the stage where

power failed.

SAFETY

•

Alarm card safeties/failsafes. Unique, UL safety certification to the UL 61010

standard meaning you can be assured that an independent testing lab has

confirmed the unit will fail safe.

• Idle/Preheat automatically raises the lift if no keys have been pressed for an hour

and applies just enough power to keep the muffle between 100° and 200°F. This

keeps the muffle from accumulating moisture which can turn into steam on the

next run and cause insulation cracks.

ACCURACY

• Like all Whip Mix ovens, the unit is calibrated to +/- 3 ̊ C tolerance specification.

• 1570°C max sustained temperature.

• 30 ̊C max heat rise

FIELD SOFTWARE UPGRADEABILITY VIA FLASH DRIVE

Convenient upgrades you install means no shipping the furnace back for upgrades!

SPECIFICATIONS

Dimensions |

17"W x 25.5"D x 33.24"H |

Heating Chamber Dimensions |

3.5" (9 cm) Diameter × 6.5" (16.5 cm) High |

Power Requirements 16 Amp Model |

208 – 240 VOLT 50/60Hz Single Phase, 16 Amps, 3680 Watts |

Power Requirements 20 Amp Model |

200 – 240 VOLT 50/60Hz Single Phase, 20 Amps, 4600 Watts |

Number of Programss |

30 |

Number of Stages/Program |

1-4, User Defined |

Delay Start |

0-8.0 Hours |

Maximum Heat Rate |

1-54ºF/min. (1-30ºC/min.) |

Maximum Temperature |

1570ºC (2858ºF) |

Oven Weight |

132 lbs. |

LEARNING

eBook

Why Temperature Control is Critical in Dental Ceramic Firing:

Download the eBook

Case Study

Making the Right Choice:

Download the Case Study

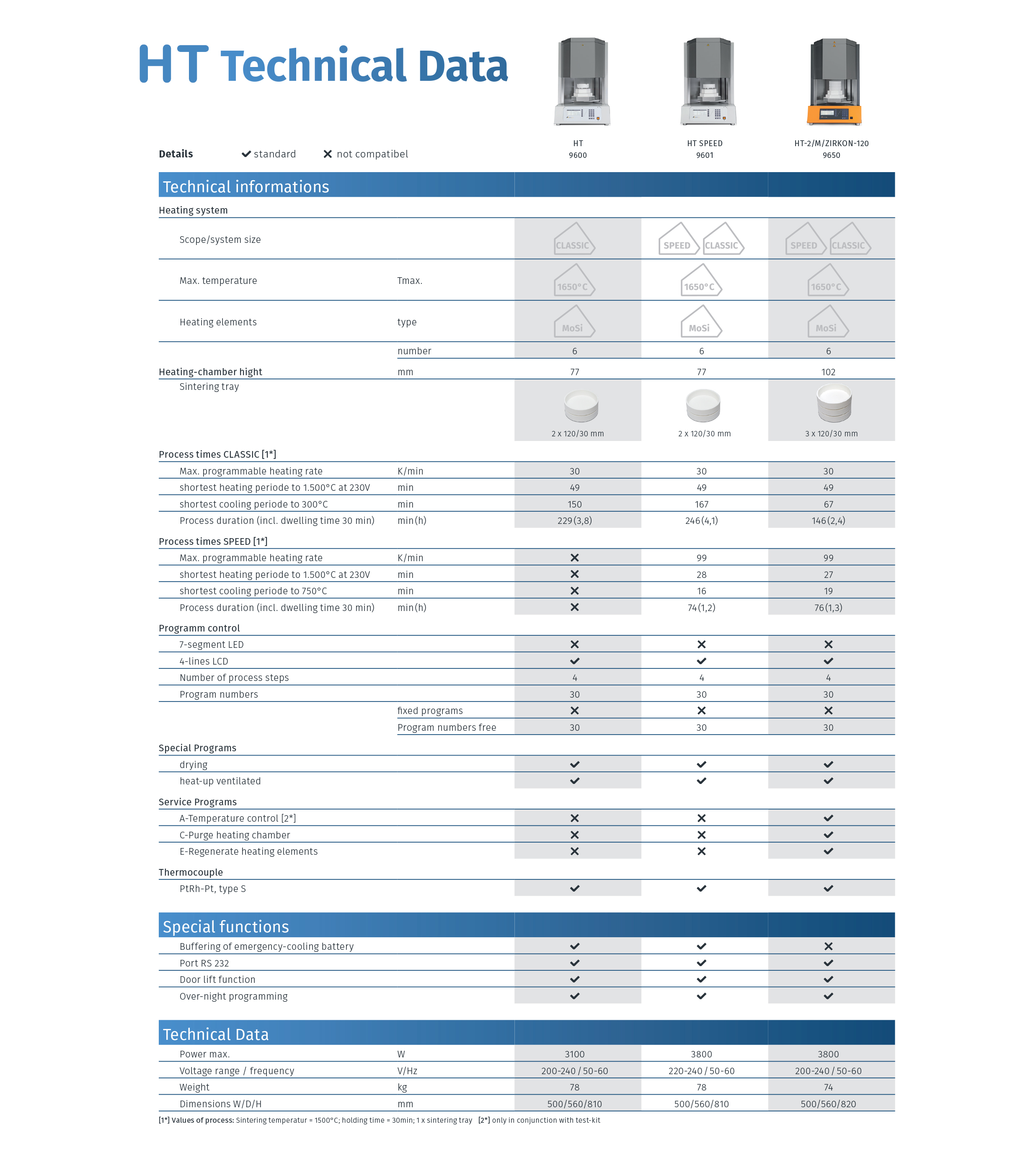

Sintering Furnaces

Mihm-Vogt supplies sintering furnaces for a wide range of applications and requirements: Models in widely differing versions and sizes are suitable for both small laboratories and large milling centers. They are the ideal complement to any CAD/CAM system. As a user, you can be flexible when choosing your materials, without relying on one particular brand, as all our high-temperature furnaces can be programmed individually.

Mihm-Vogt supplies sintering furnaces for a wide range of applications and requirements: Models in widely differing versions and sizes are suitable for both small laboratories and large milling centers. They are the ideal complement to any CAD/CAM system. As a user, you can be flexible when choosing your materials, without relying on one particular brand, as all our high-temperature furnaces can be programmed individually.

Mihm-Vogt speed sintering furnaces save you valuable production time and shorten the sintering process substantially, depending on the material. Speed programs use less energy and therefore help to protect the environment and reduce your consumption costs.

Sintering

Mihm-Vogt only use high-quality MoSi2 heating elements for our equipment. The highest programmable temperature is 1650 °C, but the heating elements are suitable for a temperature range reaching up to 1800 °C. Thanks to this scope in the upper temperature range, the heating elements are placed under less stress as they are not heated to their uppermost limit. This has a positive effect on their service life.

Mihm-Vogt only use high-quality MoSi2 heating elements for our equipment. The highest programmable temperature is 1650 °C, but the heating elements are suitable for a temperature range reaching up to 1800 °C. Thanks to this scope in the upper temperature range, the heating elements are placed under less stress as they are not heated to their uppermost limit. This has a positive effect on their service life.For every sintering process, there are programs of four steps available for you to use, which you can set individually. This means you can be flexible and use a variety of available sintering materials; thanks to the large temperature range, you can also use translucent zirconium oxide, for example. Choose the required end time for a process and the furnace will start automatically.

Mihm-Vogt sintering furnaces have an emergency cooling system with off-grid housing cooling, which means that they are protected from overheating even in the event of a power cut. The ventilation continues working to ensure that, even at high sintering temperatures, your equipment is sufficiently cooled and cannot become damaged.

Our various models are adapted to your needs thanks to their sizes and equipment:

HT-S

The compact and versatile HT-S sintering furnace (see figure on the left) was developed for laboratories with a limited number of restorations or laboratories with parallel milling systems. It allows you to save up to nine programs.HT

The HT high-temperature furnace supports you with high workloads and ideally complements your CAD-CAM system in the milling center. In addition to a large-capacity tray, this furnace also offers scope for an optional second tray. Additional functions, such as a pre-drying phase or ventilated heating, extend your application possibilities further.Speed Sintering

The market now offers zirconium oxide ceramics that withstand higher heating and cooling rates, and therefore can be sintered through in shorter periods of time. For these shorter sintering processes, you need the right equipment: The HT-S Speed and HT Speed sintering furnaces (see figure on the left). Your heating system is specially developed to meet the particular requirements of speed sintering. Even the extremely long-lasting speed sintering trays are perfectly suited to this.

For you, this simply means you save huge amounts of time and have a better workload. Until now, sintering processes have been very time-consuming. However, by using a suitable material, the program duration can be significantly reduced. Sintering cycles that have been shortened so significantly use less energy and are therefore better for the environment, while also lowering your consumption costs.

The speed heating elements we use also offer you an additional bonus: Unwanted yellow/green discoloration does not occur. Mihm-Vogt speed sintering furnaces are therefore perfectly suited to use with translucent zirconium oxide.

In addition to all of these benefits, all the functions included on our standard sintering furnaces are also available. The intelligent electronics on the Mihm-Vogt speed sintering furnaces automatically detect whether you are using a standard program or a speed program.

- Address: 29627 West Tech Dr.

Wixom, MI 48393 - Toll Free: + 1 (855) 687 7941

- Office: + 1 (248) 926 8810

- Fax: + 1 (248) 926 9085

- Email: info@axsysinc.com

Recent Posts

Axsys Dental Solutions Expands Product Portfolio

Axsys Dental Solutions Announces New Line of PMMA CAD/CAM Discs & Acrylic Teeth

Axsys Dental Solutions Expands Product Portfolio

Axsys Dental Solutions Announces New Line of High Translucency Zirconiauseful links

- Whitepaper: Construction

Characteristics of an Effective Dental

Milling Machine - 10 Questions to Ask Before

Purchasing a New Dental Milling

Machine - Axsys Dental Solutions Personal

Care Support Program - Axsys Dental Solutions Corporate

Datasheet - ROI Calculator: Restorative

- ROI Calculator: Custom Abutments

Copyright © 2017 | www.axsysdental.com | All rights reserved.