With the Axsys Dental Solutions Custom Abutment Manufacturing System you can stop out-sourcing your implant abutment business and increase your profits by as much as 300%.

With the Axsys Dental Solutions Custom Abutment Manufacturing System you can stop out-sourcing your implant abutment business and increase your profits by as much as 300%.

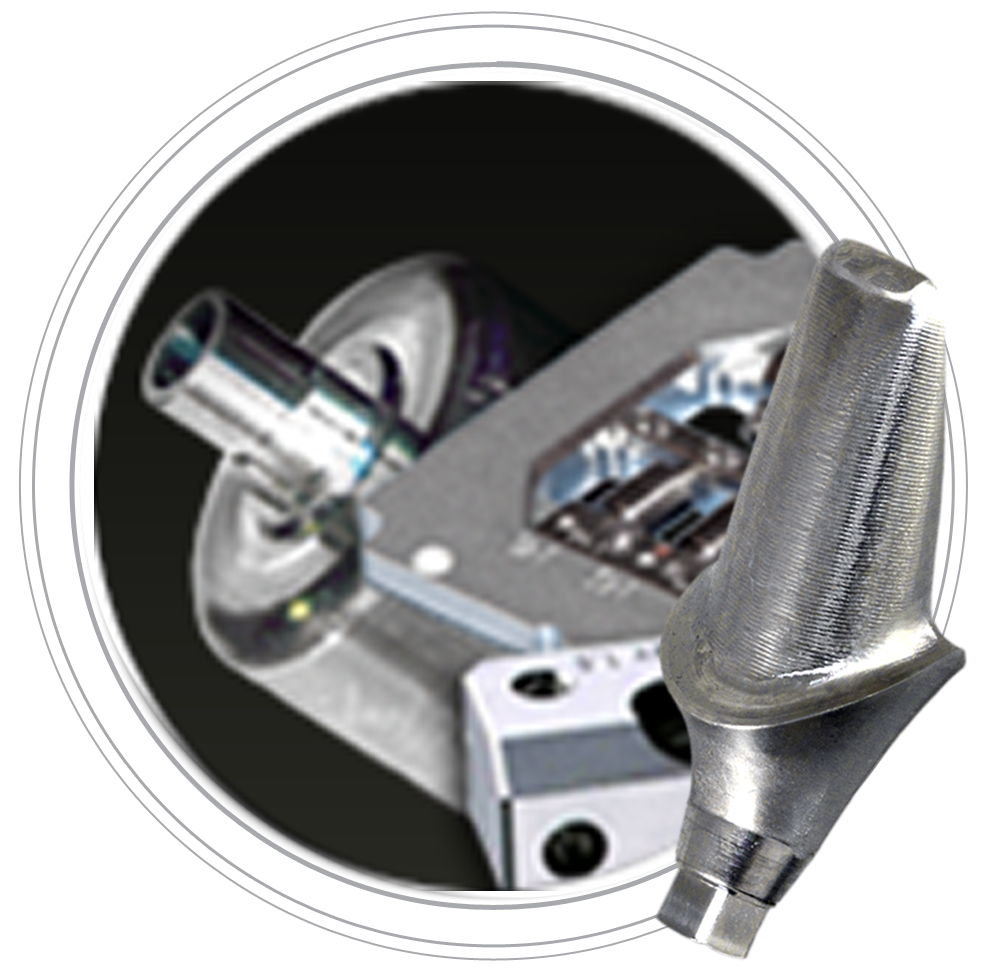

Couple the accuracy and rigidity of our VersaMILL Precision Dental Machining Centers with the highly-efficient and comprehensive machining templates developed by our expert team of Application Engineers to quickly produce custom abutments from NT-Trading FDA registered blanks and our 6-Unit abutment fixture; the quality of which will astonish patients and customers alike.

NT-Trading, NT-Preform® single-unit pre-milled abutment blanks are ideal for fabricating hybrid abutments and screw-retained crowns and can also be used in bridge frameworks.

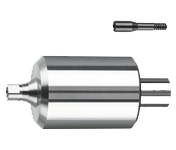

NT-Preform abutment blanks are made of high quality Grade 5 titanium and are available for the most popular implant systems. System components include; groove indexed lab analog's, milling screws, abutment screws and abutment fixture grips for use in our versatile 6-position abutment fixture.

The latest version of our NT-Abutment cartridge for the VersaMILL 5X-200 introduces many advantages and improvements over the standard product provided by NT-Trading.

The latest version of our NT-Abutment cartridge for the VersaMILL 5X-200 introduces many advantages and improvements over the standard product provided by NT-Trading.

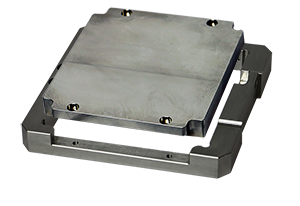

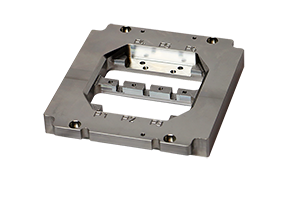

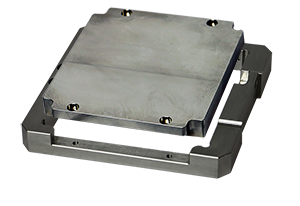

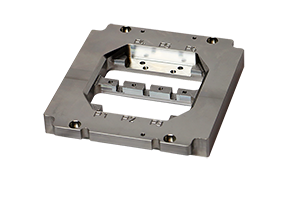

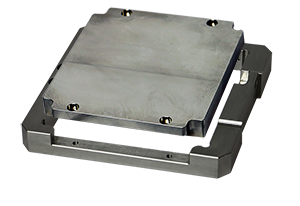

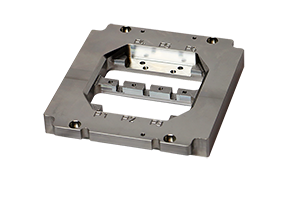

Our abutment manufacturing system utilizes the same base fixture utilized for zirconia cartridges. This time and money saving approach, coupled with the ability to easily swap between the VersaMILL’s dual coolant tanks makes transitioning between machining titanium abutment blanks and zirconia easier than ever.

The abutment cartridge mounts directly into the standard VersaMILL 5X-200 fixture so there is no need for technicians to go through a complicated and lengthy calibration routine.

Automated Machining of Even the Most Severe Abutment Designs.

Over 40 years of digital design and manufacturing experience enables us to provide the most comprehensive custom abutment machining solution handling the widest variety of design features and abutment characteristics.

Over 40 years of digital design and manufacturing experience enables us to provide the most comprehensive custom abutment machining solution handling the widest variety of design features and abutment characteristics.

Couple Axsys expertise with the quality and precision of Versamill machine technology to produce restoration of superior quality:

Our team of expert Dental, CAD/CAM and manufacturing experts have leveraged our 40 years of experience to provide significant enhancements to the standard deliverable abutment design and machining libraries. These modifications include enhancements to the user interface, milling strategies, CAD libraries and more and greatly improve robustness, restoration quality, tool life, surface finish, machine time and reliability.

Our enhanced CAD libraries virtually eliminates hand-finishing and provides significantly more flexibility in abutment design.

Small subgingival concave radius requires special tooling and consideration of machining conditions.

Review the products.

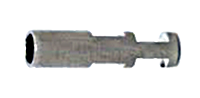

Milling blank for individual one-piece titanium abutments used in the CAM process.

Milling blank for individual one-piece titanium abutments used in the CAM process.

Precise prefabricated implant interface.

Available in two different gingiva heights.

Individual abutment design by prosthetical terms.

Optimal interface protection by bilateral fixing in preform holder during the milling process.

Primary telescopes on implants.

Mesio-structures for crowns and bridges.

Occlusal screwable structures.

Titanium Grade 5 ELI

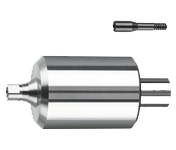

For implant supported individual hybrid abutments.

For implant supported individual hybrid abutments.

Engaged unit.

For individual abutment designs.

Large glue surface providing durable solid connection to the base.

For conventional use as well as for use in the CAD/CAM process.

For individual glued ceramic abutments (zirconia lithium disilicate) or synthetics (PMMA, PEEK, composite)

Titanium Grade 5 ELI

Angle compensation for divergent implants available in different gingiva heights and angled version

Angle compensation for divergent implants available in different gingiva heights and angled version

Self – centering conical connection.

Maximum flexibility of divergent implant positions.

Stressless fitting by optional adhesive connection (female part).

Female part compatible between the different implant systems and diameters.

Force application caused by tube shape and integrated screw (Straight Abutment) or mounted screw (Angled Abutment).

Bars.

Bridges.

Non-engaging structures.

Titanium Grade 5 ELI

Scanbody for high-precision implant position transfer.

Scanbody for high-precision implant position transfer.

Exact positioning by metal interface.

Conceived for intra-oral scanners.

Screw integrated.

X-ray detectable.

Rotatable to facilitate interproximal crowding.

Different shape geometry ensures a perfect transfer in CAD software in case of incomplete scanning detection.

Scanbody for model scanning.

Scanbody for inter-oral scanning.

Non-engaging structures.

Tolerance 2-3µm

Digital Implant Model-Analog available for 24 implant systems.

Digital Implant Model-Analog available for 24 implant systems.

Implant analog for digital model manufacturing in the model builder library.

Two-piece repositionable implant analog.

Precise positioning.

Positional adjustment possible.

Analog design supports precise repositioning of removable gingiva mask.

For model manufacturing in digital workflow.

Scanbody for inter-oral scanning.

Non-engaging structures.

Stainless steel

Titanium Grade 5 ELI.

Improvements in all areas of implant technology.

Improvements in all areas of implant technology.

The nt-trading company focuses on the development and the production of premium products in the field of dental implant technology. More and more customers all over the world benefit from our high standards in quality, precision and innovation. With our products we improve prosthetic production processes and optimize the prosthetic treatment possibilities.

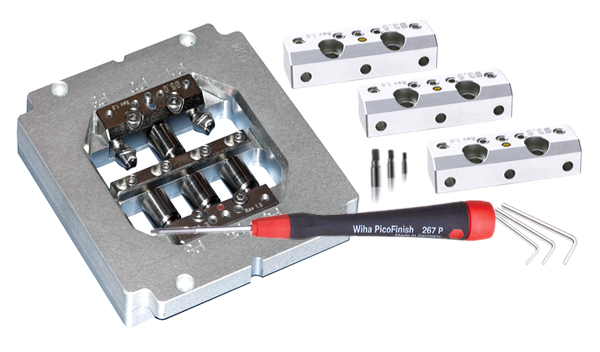

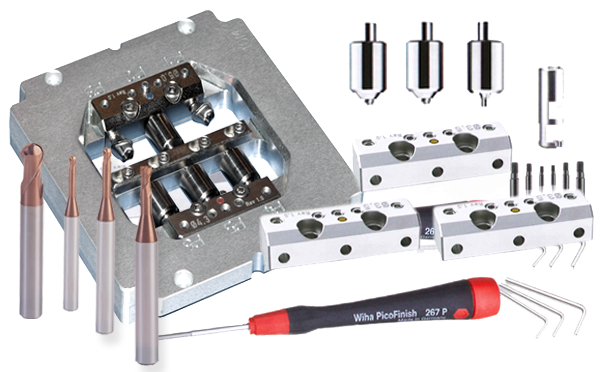

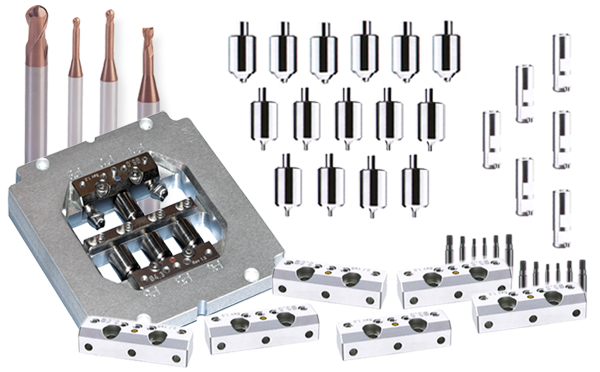

We've put together some money saving starter packages containing the key components of our abutment machining solution.

All components are compatible with the NT-Trading fixture for the VersaMILL and other supported milling machines and designed to provide you with all that is necessary to get you up and running as quickly and easily as possible.

Components include:

1. Package does NOT include Abutment Grip Inserts.

2. Fixture Insert Finish Machined on Your VersaMILL.

3. Inspected and Assembled for Complete Accuracy

and Repeatability.

|

6-Unit Fixture w/Calibration Unit & Cartridge Blank. |

|

Rough-machined Versamill Cartridge Blank w/Finishing Fixture Toolpath, Inspection & Assembly. |

|

Titanium Tooling Package: (2) 3mm, (1) 2mm, (1) 1.5mm, (1) 1.0mm TiSin Ball Nose Endmills. |

1. Fixture Insert Finish Machined on Your VersaMILL.

2. Inspected and Assembled for Complete Accuracy

and Repeatability.

|

6-Unit Fixture w/Calibration Unit & Cartridge Blank. |

|

Rough-machined Versamill Cartridge Blank w/Finishing Fixture Toolpath, Inspection & Assembly. |

|

Titanium Tooling Package: (2) 3mm, (1) 2mm, (1) 1.5mm, (1) 1.0mm TiSin Ball Nose Endmills. |

|

(1) Each Abutment Grip Inserts: 3.5mm, 4.3mm or 5.0mm. |

|

Screw & Wrench Set. Includes: (9) Analog Holding Screws, (4) Fixture Grip Holding Screws, Hex Wrench Set & Fixture Grip Wrench. |

|

Lab Analog (Nobel Replace Select® Compatible). |

|

Axsys Dental Solutions Expert Abutment Machining Templates. |

|

NT-Preform w/ Milling Screw (4.3mm Nobel Replace Select® Compatible). |

1. Fixture Insert Finish Machined on Your VersaMILL.

2. Inspected and Assembled for Complete Accuracy

and Repeatability.

|

6-Unit Fixture w/Calibration Unit & Cartridge Blank. |

|

Rough-machined Versamill Cartridge Blank w/Finishing Fixture Toolpath, Inspection & Assembly. |

|

Titanium Tooling Package: (2) 3mm, (1) 2mm, (1) 1.5mm, (1) 1.0mm TiSin Ball Nose Endmills. |

|

(2) Each Abutment Grip Inserts: 3.5mm, 4.3mm or 5.0mm. |

|

Screw & Wrench Set. Includes: (18) Analog Holding Screws, (4) Fixture Grip Holding Screws, Hex Wrench Set & Fixture Grip Wrench. |

|

(1) Each All Supported Lab Analogs. |

|

Axsys Dental Solutions Expert Abutment Machining Templates. |

|

(1) Each All Supported NT-Preform w/ Milling Screw. |

| SYSTEM | ASSOCIATED LAB ANALOG |

| Replace Select® | Lab Analog 3.5mm NP |

| SynOcta® | Lab Analog 3.5mm NN |

| Bone Level® | Lab Analog 3.3mm NC |

| Astra® | Lab Analog 3.5mm/4.0mm |

| Zimmer® | Lab Analog 3.5mm |

| 3i Certain® | Lab Analog 3.4mm |

| Nobel Active® | Lab Analog 3.5mm NP |

| SYSTEM | ASSOCIATED LAB ANALOG |

| Replace Select® | Lab Analog 4.3mm RP |

| SynOcta® | Lab Analog 4.8mm RN |

| Bone Level® | Lab Analog 4.1mm/4.8mm |

| Astra® | Lab Analog 4.5mm/5.0mm |

| Zimmer® | Lab Analog 4.5mm |

| 3i Certain® | Lab Analog 4.1mm |

| Nobel Active® | Lab Analog 4.3/5.0mm RP |

| SYSTEM | ASSOCIATED LAB ANALOG |

| Replace Select® | Lab Analog 5.0mm WP |

| SynOcta® | Lab Analog 6.5mm WN |

| Zimmer® | Lab Analog 5.7mm |

| 3i Certain® | Lab Analog 5.0mm |

Development dolor sit amet, consectetur adipiscing elit. Phasellus ac fringilla nulla, sit amet consequat eros. Pellentesque pharetra blandit commyolk. Phasellus massa nisl, feugiat ac bibendum et, dictum id ipsum. Quisque sit amet accumsan tortor It has survived not only five centuries, but also the leap into electronic typesetting, remaining essentially unchanged many web sites.

Nullam turpis. Cras dapibus, orci rutrum adipiscing luctus, nisl magna tempus urna, id porttitor nunc arcu et mauris. Suspendisse id justo id nisi suscipit porttitor. Pellentesque aliquet, leo id vestibulum eleifend, magna sem iaculis risus, quis volutpat turpis quam in tortor. Morbi euismod nulla aliquet felis. Sed nisi neque, fermentum sit amet, vestibulum et, pretium sit amet, tortor. Nulla egestas pede. Phasellus ac enim. Vivamus risus. Aliquam lacinia ante quis nibh. Curabitur velit. Pellentesque habitant morbi tristique senectus et netus et malesuada fames ac turpis egestas.