3D Dental Printers from EnvisionTEC

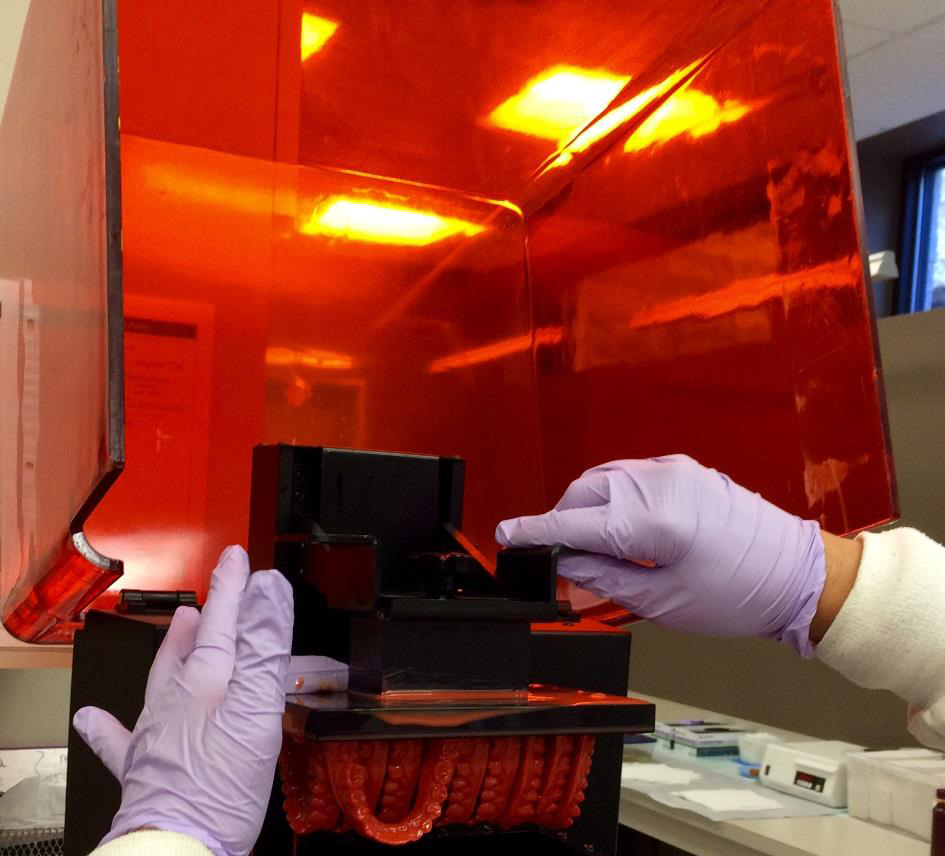

Because Axsys Dental Solutions believes the future of dentistry is digital, we represent the EnvisionTEC Dental 3D printers.

Because Axsys Dental Solutions believes the future of dentistry is digital, we represent the EnvisionTEC Dental 3D printers.

EnvisionTEC has designed a 3D printing solution for almost every dental need. So whether you run a small dental or orthodontic practice, or the largest lab, you can reap the benefits of greater capacity, faster turnaround, smoother workflow, and happier customers and patients.

Whether you wish to 3D print bridges, crowns, models, surgical drill guides, night guards or more, EnvisionTEC’s 3D printers combine high-quality 3D printing technology with an industry-leading library of dental materials. Our technology is being rapidly adopted by dentists, orthodontists and dental labs looking to lower costs, provide more convenient patient care and who desire tighter control over treatment plans.

EnvisionTEC 3D Printers Deliver

EnvisionTEC 3D printers deliver labor and material cost reduction as well as higher clinical quality and consistency throughout the manufacturing process. Labs need to compete with offshore production. Our low-cost, high-throughput solutions offer the requisite quality to level the global playing field and improve dental lab competitiveness.EnvisionTEC 3D printing solutions are optimized for a number of materials representing a broad portfolio of dental and orthodontic applications. Whether you use 3Shape, Dental Wings, or any other design software product, a finished product is only a few clicks away.

As software and material upgrades become available, this information is provided to EnvisionTEC customers. We are in constant communication with the R&D teams of the most recognized dental CAD software companies to ensure a seamless workflow that delivers consistent manufacturing quality.

Fast, Easy, Accurate & Flexible

EnvisionTEC systems are being integrated into the digital workflow throughout the global dental industry as CAD/CAM and 3D printing are changing the dental industry at a very fast rate. The success of the digital dental lab implementation relies heavily on:

EnvisionTEC systems are being integrated into the digital workflow throughout the global dental industry as CAD/CAM and 3D printing are changing the dental industry at a very fast rate. The success of the digital dental lab implementation relies heavily on:

- Availability and ease of use of CAD software to design restorations and models from scan data.

- Highly accurate, reliable 3D printers to replicate that data reliably and accurately.

- A wide variety of materials for a broad spectrum of dental applications.

EnvisionTEC 3D printing solutions are optimized for a number of materials representing a broad portfolio of dental and orthodontic applications. Whether you use 3Shape, Dental Wings, or any other design software product, a finished product is only a few clicks away

EnvisionTEC Printer Families

See All Dental Printers

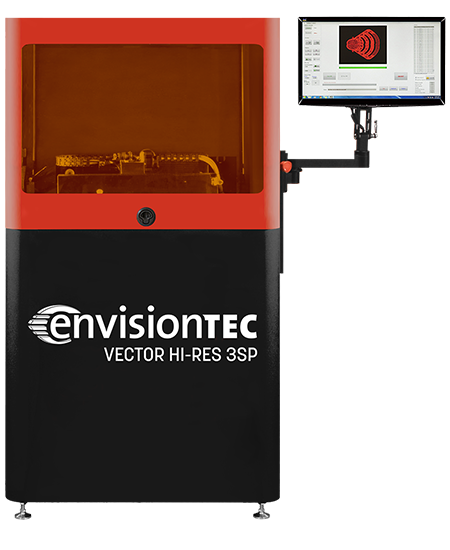

Since the founding of EnvisionTEC in 2002, with pioneering DLP (Digital Light Processing) technology, Envisiontec have been innovators in the 3D printing space.

But they don’t innovate for the sake of innovation. Envisiontec does it to solve the real-world problems of their customers – professionals who manufacture prototypes, tooling, parts and final products for demanding cost-sensitive customers in a variety of industries.

Today, Envisiontec provides more than 40 models of 3D printers based on six distinct process technologies.

Envisiontec printers are known for delivering excellent precision, surface finish, functionality and speed. And each of our families of printers below offers something special to meet the unique needs of our fast-growing list of customers and the industries in which they operate.

UV Light Curing Box

Final step after 3D printing

The UV Light Curing Box for ULTRA 3SP and Xtreme 3SP is a UV light flood lamp for the post-processing of UV sensitive curing resins for industrial, dental, medical, and other applications.

Vida cDLM

More powerful than ever

The Perfactory Vida cDLM with EnvisionTEC's patented Continuous Digital Light Manufacturing technology and offers high resolution combined with blazing speeds reduces the need for support structures during 3D builds, meaning less finishing is necessary.

3-Dent

Perfect for larger dental labs

The 3-Dent was designed specifically for the production of high-quality crown and bridge models with removable dies. Up to 9 full arches or 34 quads can be produced in each build.

Read More

Vida

Highly Accurate 3D Printer

One of EnvisionTEC's best-selling 3D-printers for the dental industry, the Vida is extremely versatile. Perfect for small dental labs or practices, the Vida is capable of printing dental or orthodontic models, surgical guides, partial frameworks, and bite guards.

VIDA HI-RES

50 µm (0.002 in.) resolution

The Vida Hi-Res is the perfect choice for small dental labs and practices who need a higher resolution 3D printing option. Crown and bridge models with removable dies, partial frameworks, and drill guides will all be produced with exceptional fit and surface finish.

VIDA HI-RES CROWN & BRIDGE

35 µm (0.0014 in.) resolution

Boasting the highest resolution available in the Vida Series, the C&B model is ideal for the production of extremely precise dental crowns, bridges, and copings in both a castable and pressable material or in an FDA-approved material for long-term temporaries.

EXTREME HIGH-RES ESP

Excellent surface finish and detail.

For those in need of a large build area and a higher resolution of 50 µm (0.002 in.), the Xtreme 3SP Hi-Res is the ideal solution. From prototypes to production parts, the Xtreme 3SP Hi-Res provides excellent surface finish and detail.

Read More

MICRO PLUS FAMILY

Micro Plus – Advanced Desktop 3D Printers

This professional-grade desktop 3D printer family uses advanced DLP technology backed by more than a decade of development and exclusive patent-protected processes that make these printers truly superior.

P3 DDP

Producing the finest detail in the shortest period of time

The P3 DDP is an economical choice for small dental laboratories and can produce up to 70 copings and crowns in under three hours.

P4 DDP

Perfactory 4 Digital Dental Printer

An excellent dental laboratory staple, the P4 DDP can print up to 95 copings and crowns in less than two hours. It is also capable of printing long-term temporaries, partials, and full arch or quad models.

P4 DDP XL

Minimal time and effort required to change over between materials.

The P4 DDP XL offers the largest build area in the P4 DDP series. Large laboratories will appreciate the flexibility to produce surgical drill guides, dental and orthodontic models, partial frameworks and night guards all on the same versatile machine.

Read More

P4 DDP M

Low cost, easy to maintain, and user-friendly

With a medium-sized build envelope among the P4 DDP series, the P4 DDP M adds to the production capacity of dental applications for laboratories. The P4 DDP M is able to print up to 2876 cubic cm (175.5 cubic in.) in a single build.

3D Printing Materials for the Dental Industry

See All Dental Materials

The EnvisionTEC line of Perfactory 3D printing materials are formulated for use with printers that use the Perfactory DLP® technology to grow exceptionally accurate and functional parts, without sacrificing speed of build time. We offer a wide range of materials with different qualities for our 3D printers, including castable resins that contain some wax for easy burn-out in investment castings. We also offer materials that are flexible, transparent and functional for a variety of uses.

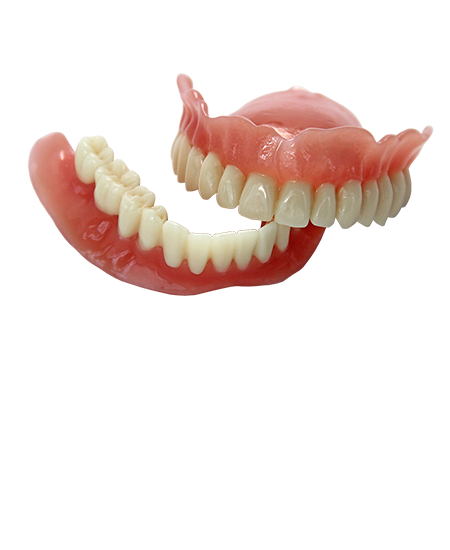

E-DENTURE

Low shrinkage compared to standard PMMA bases.

EnvisionTEC's E-Denture material is an FDA-approved, biocompatible Class IIa material suitable for 3D-printing all types of denture bases.

E-IDB

Cuts bracket application time in half, saving the patient time in the chair.

E-IDB is a 3D printing material allowing for the production of indirect bonding trays for the precise placement and release of orthodontic brackets.

E-MODEL 3SP

Perfect for a wide variety of modeling needs.

E-Model 3SP is a tough material, suitable for high quality prototypes of items in categories such as automotive and consumer goods as well as stable enough for production-quality end use parts. It is also ideal for dental model applications.

Read More

E-DENT 100

For the manufacturing of long term crown and bridge provisionals.

EnvisionTEC’s E-Dent 100 is a light-cured micro-hybrid filled dental crown and bridge dental material for long term temporaries built on the Perfactory High Productivity DDP machine. Provisionals are photo polymerized on a voxel-by-voxel basis (volumetric pixel) of the liquid resin.

E-GUARD

Superior to traditional methods of manufacturing bite & night guards.

E-Guard is a biocompatible transparent material. for the production of accurate bite splints and night guards on the Perfactory® line of 3D Printers. The results produced by combining E-Guard with EnvisionTEC technology are superior to traditional methods of manufacturing.

E-GUM

Allows for precise reproduction of the gingival margin.

E-Gum is used to create flexible gingival masks for use in combination with 3D printed dental models, simulating the flexibility of the patient's gum in order to adjust dental prostheses properly

E-DENT 400

Full crowns or multi-unit bridges can be printed & cut back.

EnvisionTEC's E-Dent 400 printing material is an FDA-approved solution for the accurate 3D printing of crowns and bridges for long-term temporary use.

Read More

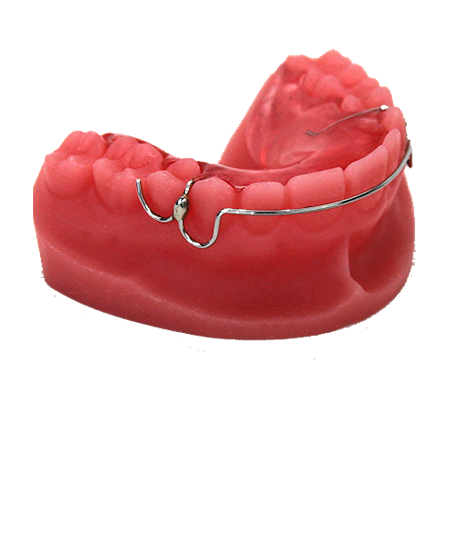

E-APPLIANCE

Excellent strength and durability with extensive design latitude.

Specially designed nano-filled 3D printing material that works reliably with both polyvinyl alcohol based separators and tin foil substitute for a “salt and pepper” technique of producing an orthodontic appliance.

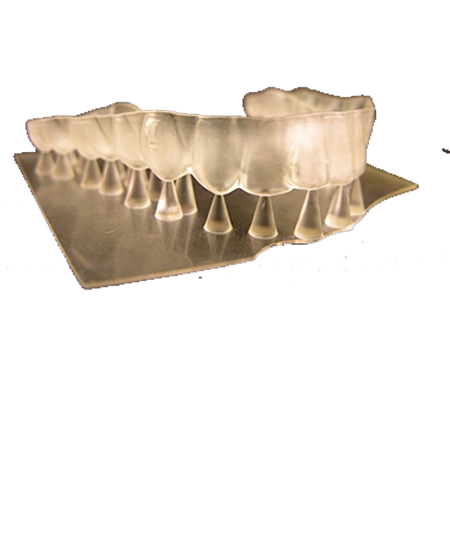

CLEAR GUIDE

The clearest material available on the market today.

Clear Guide is a crystal clear 3D printer material for the production of accurate drill guides. The results produced by combining Clear Guide with EnvisionTEC technology are superior to traditional methods of manufacturing implant placement guides. The clearest 3D printer material available on the market today allows for maximum visibility.

PRESS-E-CAST

Very low thermal expansion during burnout producing a high quality surface finish.

A 3D printing photopolymer designed for producing wax copings, crowns and bridges up to 16 units. The material has a very low thermal expansion, which eliminates cracking of investment and produces a porous free material with a perfect margin fit. It can also be used for press on ceramic.

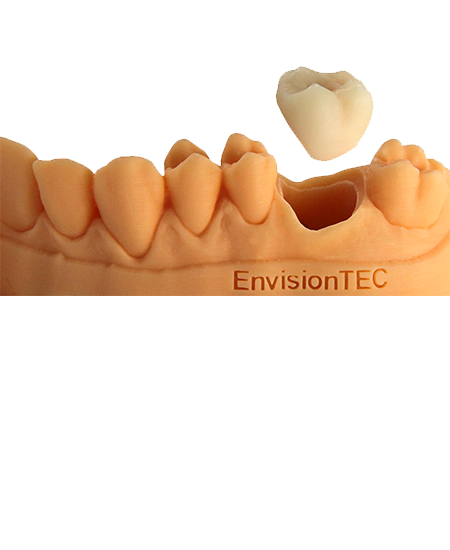

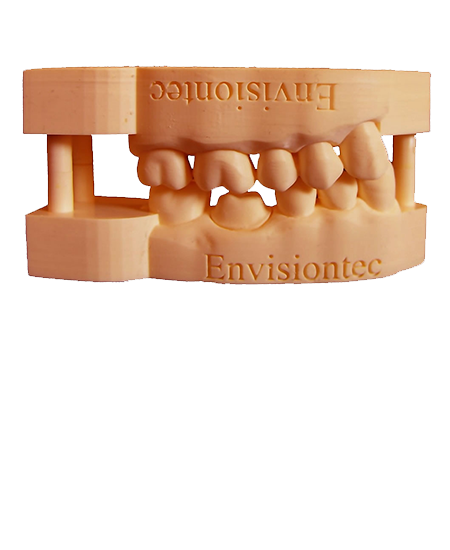

E-DENSTONE

Staggering one inch build in under 90 minutes at 35 micron Z resolution.

The peach color E-Denstone creates highly accurate models with removable dies similar to the standard gypsum color. The matte finish allows models to be scanned accurately for verification purposes and the high viscosity of the formula produces superior details and surface finish.

Read More

E-PARTIAL

Maintains flexural strength to ensure clasp flex without breakage.

E-Partial material was developed for creating wax-like partial dentures for direct investment casting in semi precious metals. E-Partial material maintains flexural strength to ensure clasp flex without breakage. The stiffness of E-Partial allows for production of a very hard retention grid and super tight thin clasps to deliver a metal partial with the perfect fit every time.

- Address: 29627 West Tech Dr.

Wixom, MI 48393 - Toll Free: + 1 (855) 687 7941

- Office: + 1 (248) 926 8810

- Fax: + 1 (248) 926 9085

- Email: info@axsysinc.com

Recent Posts

Axsys Dental Solutions Expands Product Portfolio

Axsys Dental Solutions Announces New Line of PMMA CAD/CAM Discs & Acrylic Teeth

Axsys Dental Solutions Expands Product Portfolio

Axsys Dental Solutions Announces New Line of High Translucency Zirconiauseful links

- Whitepaper: Construction

Characteristics of an Effective Dental

Milling Machine - 10 Questions to Ask Before

Purchasing a New Dental Milling

Machine - Axsys Dental Solutions Personal

Care Support Program - Axsys Dental Solutions Corporate

Datasheet - ROI Calculator: Restorative

- ROI Calculator: Custom Abutments